PERFORMANCE AND COMFORT

WITHOUT COMPROMISE

WHY are ski boots uncomfortable?

So why this discomfort which seems inevitable, whatever the brand, the range, the price of your ski boot?

The answer is that we all have completely different morphologies, at the level of the lower leg: calf, ankle, instep, width of the foot…

However, a plastic shell is by definition rigid, so it cannot adapt to all body types.

To deal with this problem it is possible to modify the shape of the rigid shells and have slippers molded to your foot, this is called boot fitting (hyperlink to FAQ?). If boot fitting is an improvement for many skiers, it requires very precise know-how to understand each person’s morphology and is sometimes limited by the deformations that can be made to the rigid shell. In addition, these deformations sometimes evolve over time and boot-fitting does not solve the problem of comfort when putting on and taking off.

zUFO, A NEW APPROACH

To design zUFO ski boots we started from a blank sheet, without pre-conceived ideas. And the first question we had to ask ourselves was: what is a ski boot for? Whatever the type of practice (ski touring, downhill skiing, downhill skiing, and even cross-country skiing) the ski boot fulfills two main distinct functions:

- An insulating function (thermal and waterproofing)

- A mechanical function

Current designs attempt to address both topics simultaneously. At zUFO we have decided on the contrary to approach the two issues independently, which allows us to optimize both functions without having to make compromises.

Our first model of zUFO ski boot is designed for Rando / Free Rando practice but is versatile enough to go on the slopes. This versatility also represents an advantage in the face of climate change and the lack of snow in certain areas; with your zUFO shoes you will be able to adapt your practice without changing shoes.

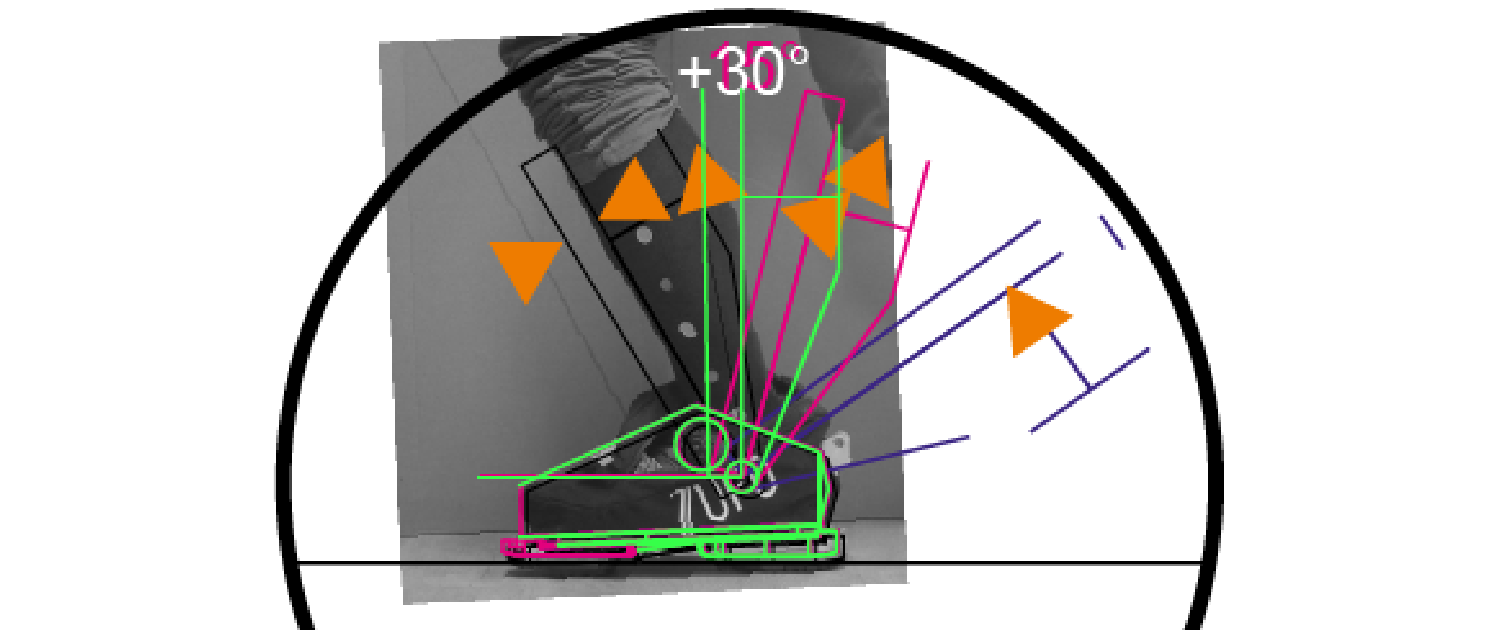

MECHANICAL FUNCTION

These efforts can be broken down into two directions:

- Back and forth to balance the support on the ski and the edges and choose your cut (the edge prints a “rail” in the snow) or skid trajectories.

- Laterally to engage the right or left edge grip with a chosen angle to make turns.

We commonly refer to Flex (hyperlink) to characterize front-to-back forces. On “classic” rigid shell technology, Flex is not standardized, not measurable and depends on many external factors (temperature, tightening of the hooks, etc.). With zUFO, Flex only depends on the suspension element which is part of the exoskeleton, like on a car, which allows you to have a measurable Flex, constant over time and adapted to everyone’s practice.

For lateral forces, if the forces are lower than front to back, the key factor is responsiveness. With zUFO, the lateral rigidity of the exoskeleton allows for very responsive edge grip transmission.

Whether from front to back or laterally, the reactivity of the exoskeleton is not disturbed by the foam of the liner which does not intervene in the force transmission chain, unlike what happens in technology. classic” hard cases.

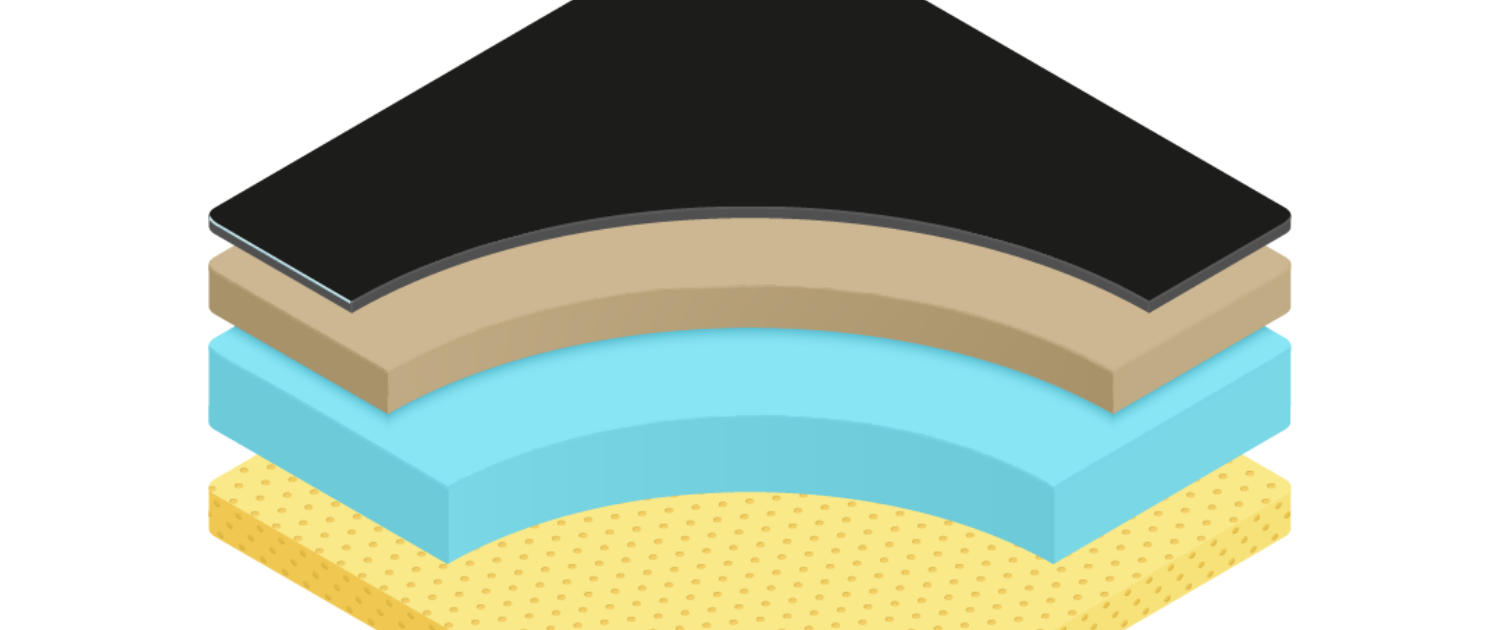

INSULATING FUNCTION

On “classic” rigid shell technology, the liner part (the internal liner under the rigid shell) provides several functions:

- mechanical (lower leg held via the rigid shell)

- comfort (relative): foam is needed between the body and the rigid shell to ensure as much as possible a rigid shell/lower leg connection that is as painless as possible

- thermal (foam is a thermal insulator)

The thicker the foam, the more comfort and thermal insulation we will have (sometimes too much?) but the more the transfer of forces will be disrupted (decrease in precision and performance).

Conversely, the less foam thickness you have, the more risk you have of having cold feet and if the performance will be higher, this will come at the expense of comfort.

With zUFO, the footwear part which comfortably and firmly holds the foot, the exoskeleton part which transmits forces and the part which ensures the thermal function (thermal insulation + waterproofing) are completely separated. The thermal function is provided by textiles that can be adapted to the conditions in which you ski, just as you can adapt your clothing to the season, the weather, the altitude, etc.

AN EXCLUSIVE MODULAR DESIGN.

The other fault that we have observed in current ski boots is their environmental impact: a lot of plastic and almost zero repairability.

That’s why even before we decided on a final concept for zUFO ski boots, we decided that our technology should be eco-designed.

Our ski boot based on an exoskeleton significantly reduces plastic (making the boot lighter), but we didn’t stop there! zUFO ski boots are easily removable and repaired thanks to a modular design. Comfortable, high-performance shoes that last a long time, so that skiing is not a guilty pleasure.

Our design was even rewarded at the CES in Las Vegas in 2023 (sustainable development innovation prize and the INPI HARDWARE AWARD) and won the PERFECTO call for projects from the French Ecological Transition Agency (ADEME) .

WHAT CHANGES

COMFORT

VERSATILITY

THE

ECO-DESIGN

We did it from the start using an eco-design method. Thus, zUFO technology is not an existing technology adapted to reduce its environmental impact but an eco-designed technology.

AND WHAT DOESN’T

SAFETY

As with rigid shell technology, the skier’s lower leg is protected against impacts with zUFO. On the other hand, there is no miracle, skiing remains a sporting practice where there is a risk depending on its commitment, whether with “classic” technology or with zUFO.

zUFO boots are compatible with existing binding standards. No need to renew all of your equipment!